EN2267- The arc tracking resistant cable solution

GENERAL INFORMATION

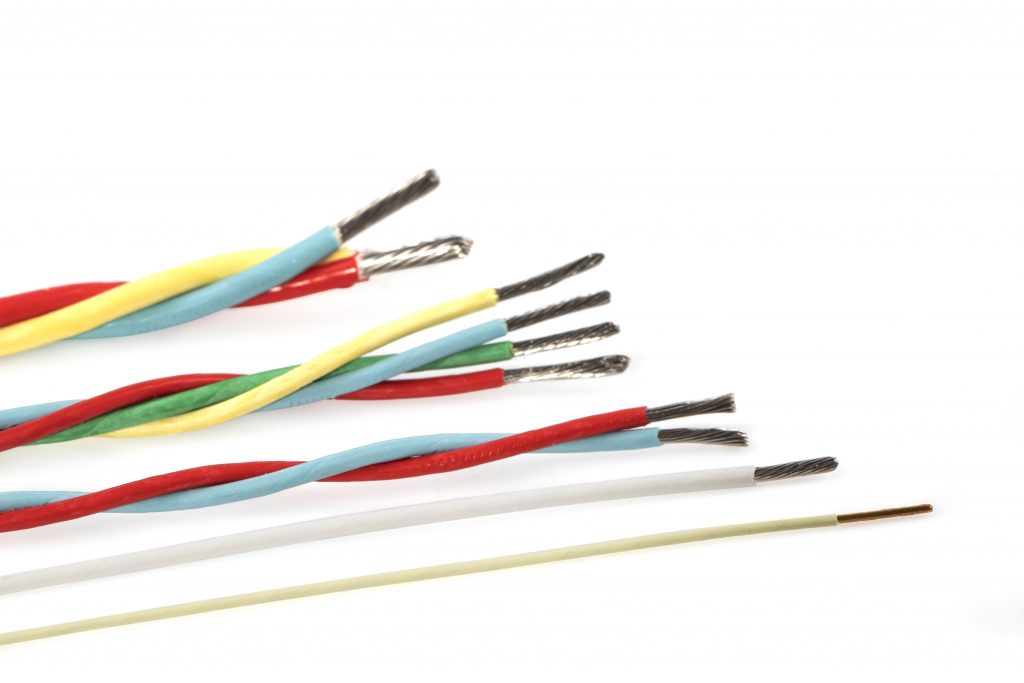

EN 2267 defines the characteristics of electrical lightweight cables mainly used on aircraft.

First of all, you should know that other standards like : ASNE0261,ASNE0262,ASNE0264,ASNE0265,ASNE0266,ASNE0267,ASNE0268 and ASNE0269 are now superseded by the EN2267-009 and EN2267-010 ( also known by all users as “DR” for the single core and “DRB“,”DRC“and “DRD” for the multicore unshielded cables ).

The purpose was to harmonize the standards installed on aircrafts, as a result the Chapters « -009 » and « -010 » are the last generation of cable widly used by customers in this industry.

Benefits of these new specifications are as follow :

Conductors are made in « nickel copper alloy » in order to whistand to very high temperature.

Wiring process recommended by the cable and Aircraft manufacturers is the crimping process ( by using M22520 crimping tool) , making these connections simple, efficient, reliable with en easy control process.

A special polyimide tape is used between the external jacket and the conductor for an excellent performance for electrical and thermal insulation with high dielectric strength.

A PTFE (Polytetrafluoroethylene) tape layer is wrapped around the cable to offer the properties of this material.

All of these properties combined with the process of manufacturing offer an Arc tracking resistant cable in order to protect your equipment

Therefore EN2267-009 and EN2267-010 offer effective thermal, chemical and electrical resistant to meet most of the aircraft areas requirements.

EN2267-010 defines a single core cable unshielded where the EN2267-009 are dedicated to identify twisted multicore cables unshielded.

Other chapters under the EN2267 standard are dedicated for other applications suitable for high voltage network ( EN2267-011 , EN2267-012 developped for 230 Volts)

or EN2267-007 and EN2267-008 for retro-fit applications.

Additionnaly, this standard offers a choice of cables suitable with laser marking.

Therefore Air Cost Control is qualified by the main Aircraft Manufacturers to mark the single core or shielded multicore cables with our laser machine.

TECHNICAL INFORMATION

Operating temperature : -55°C to +260°C.

Voltage rating : 600 Volts

Very Good Resistance to Aircraft Fluids

Arc Tracking Resistant

Color of insulation :

AWG 26 : Light yellow

AWG 22 : Light green

Other gauges : White

EXAMPLE OF BREAKDOWN

| EN2267-010 | A | 006 | S |

| STANDARD DESIGNATION | NUMBER OF CORES (REFER TO EN2267-002) | NOMINAL SECTION (REFER TO EN2267-002) | COLOUR CODING (REFER TO EN2267) |

NUMBER OF CORES

| NUMBER OF CORES | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| CODE | A | B | C | D | E | F | G | H | J |

NOMINAL SECTION

| CODE FOR NOMINAL SECTION | NOMINAL SECTION mm² | AWG |

| 001 | 0.15 | 26 |

| 002 | 0.25 | 24 |

| 004 | 0.4 | 22 |

| 006 | 0.6 | 20 |

| 010 | 1 | 18 |

| 012 | 1.2 | 16 |

| 020 | 2 | 14 |

| 030 | 3 | 12 |

| 051 | 5 | 10 |

| 090 | 9 | 8 |

| 140 | 14 | 6 |

| 220 | 22 | 4 |

| 340 | 34 | 2 |

EN 2267 Descriptions :

-003 : Ink jet printable

-004 : CO2 laser printable

-005 : UV laser printable

-006 : YAG X3 laser printable

-007 : DMA family, single ink-jet printable and multicore assembly

-008 : DM family, single UV laser printable and multicore assembly

-009 : DRA family, single and multicore assembly

-010 : DR family, single UV laser printable